A research team from the Cellulose & Wood Materials lab at Empa has developed a method to make disposable sensors more sustainable. As Empa writes in a press release, the researchers have succeeded in their efforts to develop a functional material that does not contain metal. Moreover, it is also non-toxic and biodegradable.

These sensors are increasingly being manufactured by way of 3D printing processes. Up to now, the inks used contain metal particles that make them conductive. This is used, for example, in smart packaging solutions to monitor fresh produce such as vegetables on long transport routes. However, these metals also exacerbate the problem of electronic waste.

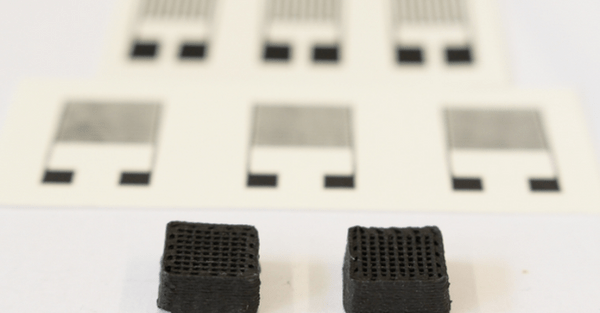

The new solution developed by the researchers uses elongated graphite platelets as a conductive material, which are mixed with tiny soot particles, all in a matrix made of the well-known biomaterial shellac. “The biggest challenge was to achieve high electrical conductivity and at the same time form a gel-like network of carbon, graphite and shellac”, explains Xavier Aeby, one of the researchers involved in the project.

“We hope that this ink system can be used for applications in sustainable printed electronics”, comments Gustav Nyström, head of the Cellulose & Wood Materials lab at Empa, in the press release, “for example, for conductive tracks and sensor elements in smart packaging and biomedical devices or in the field of food and environmental sensing”, he adds.

Related news

Contact us

Can we put you in touch with a peer company or research institute? Do you need any information regarding your strategic expansion to Switzerland's technology and business center?

info@greaterzuricharea.com