Fused filament fabrication is a process that is currently widespread among 3D printers. It involves depositing thermoplastic material layer by layer until the desired workpiece has been created. However, supporting material must be used in this process in order to create overhanging shapes with an angle of a certain size or greater. This material is removed from the object at the end of the manufacturing process but often leaves traces behind.

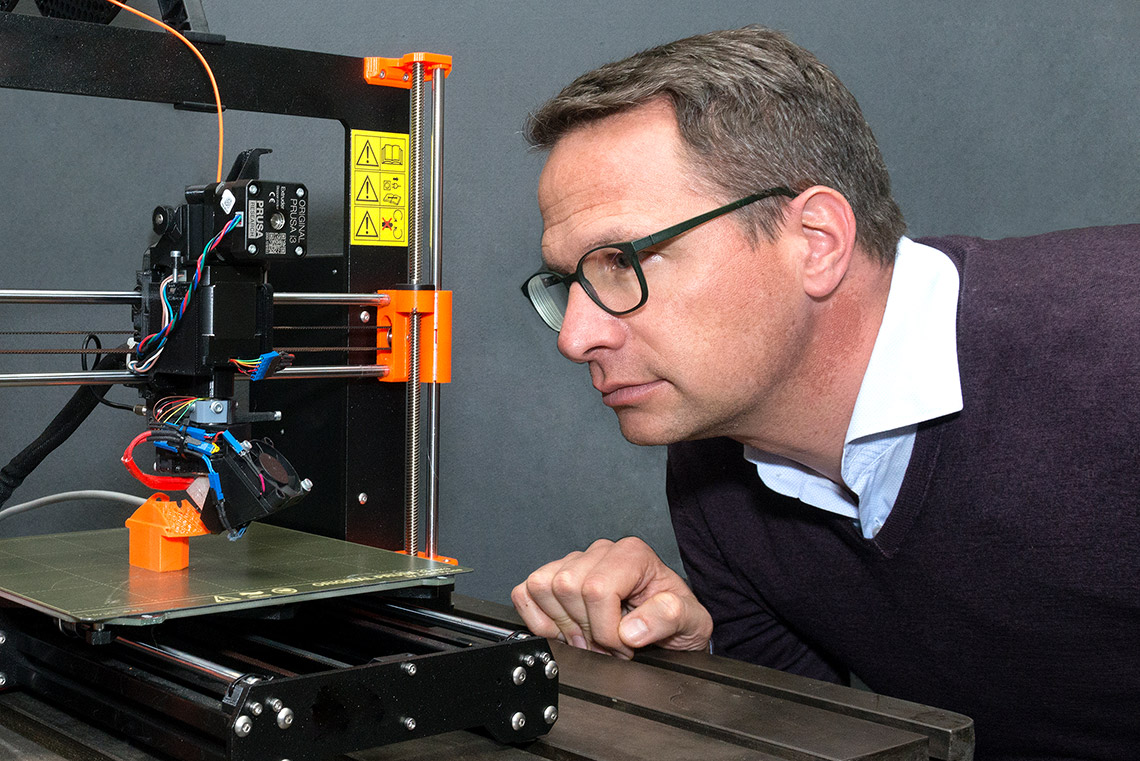

Researchers at the ZHAW have now developed a new 3D printing method that enables any shape to be created without additional supporting material. According to a press release, they have inclined the printer nozzle by 45 degrees and integrated an additional axis of rotation to do so. This means that the printer head can turn on its own axis as needed.

Wilfried J. Elspass, Head of Research/Focus Area of Systems Engineering & Rapid Prototyping at the ZHAW Institute of Mechatronic Systems, explains in the press release that printing without supporting material means: “firstly, that we require less material; second, that printing times are shorter; and third, that finishing, i.e. removing the supporting material, is now completely unnecessary.”

Together with the Institute of Applied Mathematics and Physics of the ZHAW, the researchers have developed a special data processing method for printing so that the new process can actually be applied. According to Michael Wüthrich from the Institute of Mechatronic Systems, this solution means that “time-consuming data processing is reduced using standard software, and geometrics can be printed in a fully automated way.”

If the ZHAW’s plans come to fruition, “certain manufacturers” should soon be able to implement the solution created in Winterthur as an “upgrade kit for their 3D printers” according to the university’s press release. The information given states that the development can be used to easily upgrade conventional 3D printers.

Related news

Contact us

Can we put you in touch with a peer company or research institute? Do you need any information regarding your strategic expansion to Switzerland's technology and business center?

info@greaterzuricharea.com