“Many vehicles are still waiting to be electrified,” says ecovolta CEO Pirmin Reichmuth. Demand is high, but anyone wanting to meet this demand needs the best technology and the best talent behind it. Only pioneering work will do here.

This is where ecovolta comes in with its high-performance batteries for new electric mobility solutions: high-end wooden boats, agile golf carts and even powerful tractors and municipal vehicles.

The company designs its battery solutions in its R&D center in Brunnen in the canton of Schwyz and then builds them next door in its own battery factory, which it is now developing into one of the largest of its kind in Europe.

With its platform concept, ecovolta helps vehicle manufacturers save time in development, allowing them to stay one step ahead of the competition in the electric mobility market. Its choice of location has proven to be key to its success.

Short distances for innovation

It is a major advantage that ecovolta’s research, development and production are all located close to another. The company has been using the former premises of Swiss technology group RUAG since the end of 2018.

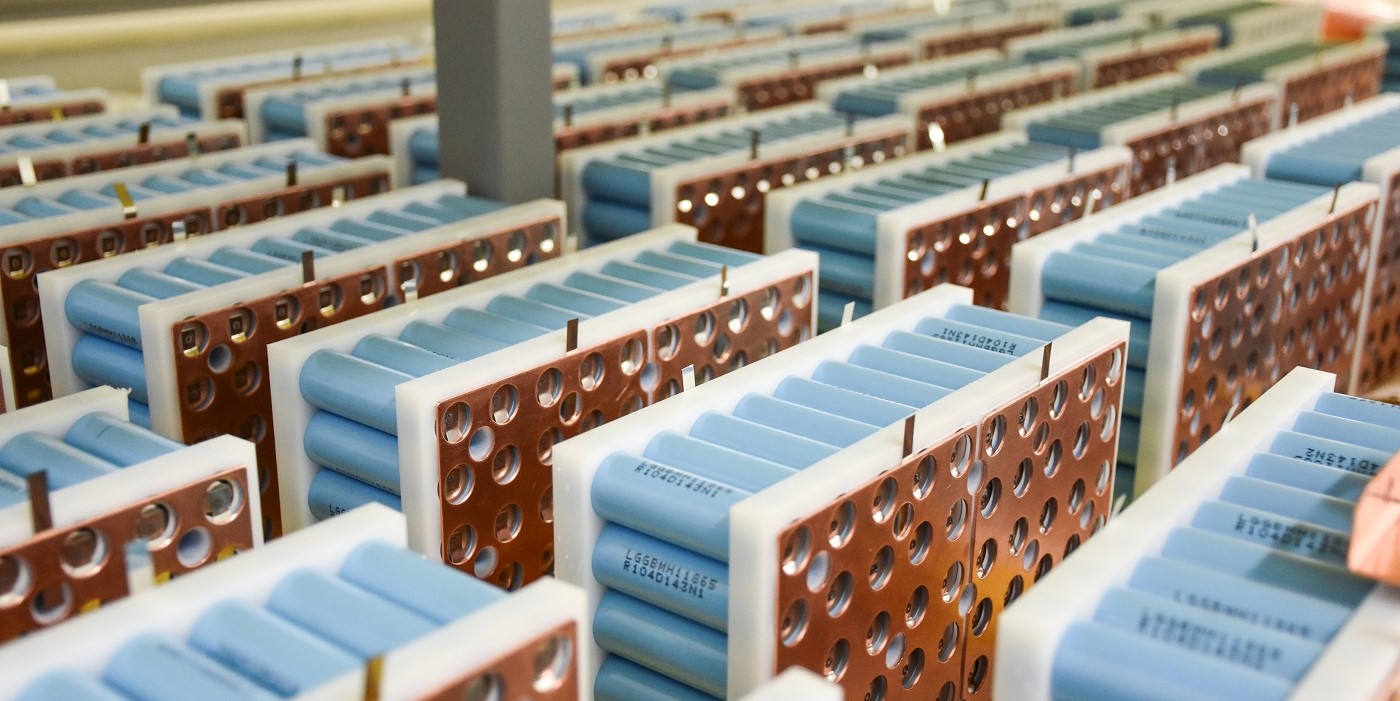

“The premises offer us the ideal infrastructure,” says Reichmuth. It is home to the R&D center and, on an area of 750 square meters, ecovolta’s fully automated production line with an annual capacity of 200 MWh of battery cells.

The company also benefits from the fact that it can find the right experts for its precise needs in the Greater Zurich Area. For example, highly specialized computer scientists from the IT hub around Zurich play an especially important role for ecovolta. Its team developed a certified battery system with an open platform concept that enables vehicle manufacturers to save up to years in development time.

“The platform makes it possible to integrate very different components,” explains Reichmuth. “This means that manufacturers can take a modular approach to construct the best possible vehicle for their application.”

For battery experts with technical experience, ecovolta need look no further than places like ETH Zurich and its Academic Motorsports Club Zurich (AMZ), which is known worldwide for its electric racecars. Especially the topics fire protection and weight are important. If an ecovolta battery pack gets damaged, the temperature only rises to the level of the cell, which then comes off to allow the rest of the battery to remain operable. Low weight is achieved through a very high energy density.

Prototypes for real applications

The battery solutions from the Greater Zurich Area are in high demand, from manufacturers in the agricultural sector such as Italian machine manufacturer Bermartec to Swiss innovation leader E-Force One. It is the first supplier of electric 18-tonne class trucks worldwide and equipped its vehicles with ecovolta’s lithium-ion batteries this past spring. Thanks to this cooperation, ecovolta batteries will soon be found in the entire Swiss transport fleet of global technology group ABB.

By Yvonne von Hunnius

Weitere News

Contact us

Can we put you in touch with a peer company or research institute? Do you need any information regarding your strategic expansion to Switzerland's technology and business center?

info@greaterzuricharea.com